Industrial Services

PLANT BOILERS

We supply boilers with new technology, heat exchange element wing tube is highly energy-efficient, and the highly advanced condensation technology ensures the efficient use of energy. The flue gas is rapidly cooled, so that the energy can be effectively utilized, saving energy and improving efficiency. Boiler solutions for: the food industry, chemical, heating industry, pharmaceutical industry, hotel industry, paper industry, textile industry, building materials industry, breeding, feed industry, mining industry, brewing industry etc

STEAM BOILERS

Pre-Mixed Condensing Steam Boiler

The closed condensate recovery system is combined with the three-pass structure, economizer and air preheater to fully utilize the heat of the gas or oil, and the heat of the high-temperature condensate is recovered from the source, which can save operating costs and improve boiler operating efficiency.

Features:

Rated thermal power: 1-20t/h

Rated thermal efficiency: 100-104%

Pressure: ≤1.6MPa

Available fuel: natural gas

Gas (Oil) Fired Vertical Steam Boiler

The shell-type fire tube structure is adopted, and the flame is burned downward to enhance the heat transfer effect, thereby reducing the convective heating area; the flow resistance of the flue gas is small, the running power consumption is low, and the operation cost is saved.

Features:

Rated thermal power: 0.5-1.0t/h

Rated thermal efficiency: 95-96%

Pressure: ≤0.8MPa

Available fuel: natural gas, liquefied petroleum gas, etc.

Gas(Oil) Fired Water Tube Steam Boiler

The boiler adopts a double-drum longitudinal "D" type arrangement structure; water, steam or steam-water mixture flows in the pipe; flame burns and flue gas flows outside the pipe, forming extremely fast steam-water flow rate and excellent water circulation system. Boiler heat absorption rate and thermal efficiency are high.

Features:

Rated thermal power: ≥10t/h

Rated thermal efficiency: 100-104%

Pressure: ≤2.5MPa

Available fuel: diesel, heavy oil, natural gas, city gas, liquefied petroleum gas, etc.

Gas(Oil) Fired Integrated Steam Boiler

The series of boilers adopts an excellent design concept. Through the condensing device, the heat of the flue gas is used in cascade, and the residual heat in the flue gas is fully absorbed, so that the boiler efficiency is greatly improved.

Features:

Rated thermal power: 1-20t/h

Rated thermal efficiency: 100-104%

Pressure: ≤3.82MPa

Available fuel: heavy oil, diesel, natural gas, city gas, etc.

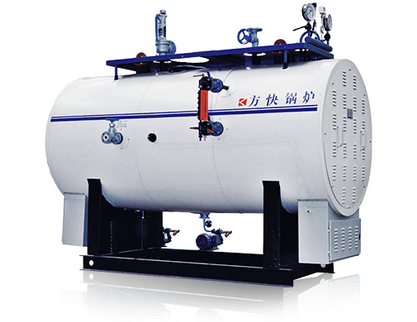

Gas(Oil) Fired Split Steam Boiler

This series of boilers is designed with a classic shell type, full-wet back, down-flow and three-pass design structure. The fuel is fully burned in the large-capacity combustion chamber, and the combustion heat load is low, which can greatly reduce the emission of harmful substances such as CO and NOx.

Features:

Rated thermal power: 1-20t/h

Rated thermal efficiency: 97-100%

Pressure: ≤3.82MPa

Available fuel: diesel, heavy oil, natural gas, city gas, etc.

HOT-WATER BOILERS

Gas(Oil) Fired Split Hot Water Boiler

This series of boilers adopts a downstream, three-pass and shell design to ensure that the fuel is fully combusted in a large combustion chamber, and fuel utilization and boiler efficiency are greatly improved.

Features:

Rated thermal power: 0.7-14Mw

Rated thermal efficiency: 91-96%

Pressure: ≤1.25MPa

Available fuel: natural gas, light oil, etc.

Gas(Oil) Fired Integrated Hot Water Boiler

This series of boilers mainly use condensing technology to recover the residual heat of flue gas, making full use of the sensible heat and latent heat of flue gas. The boiler absorbs a large amount of heat again, so the exhaust gas temperature is only 50 °C, and the thermal efficiency can be increased by more than 10%, which can save at least 4% of fuel input.

Features:

Rated thermal power: 0.7-14Mw

Rated thermal efficiency: 96-98%

Pressure: ≤1.25MPa

Available fuel: natural gas, light oil, etc.

Gas(Oil) Fired Water Tube Hot Water Boiler

The boiler is a double-drum longitudinal "D" type structure. The water, steam or steam-water mixture flows in the tubes. The flame burns and the flue gas flows outside the tubes, to ensure the good water circulation system, thus ensuring the long-term stable operation of the boiler.

Features:

Rated thermal power: 10.5-70Mw

Rated thermal efficiency: 95-98%

Pressure: ≤2.5MPa

Available fuel: natural gas, city gas, LPG, etc.

Gas Fired Vertical Hot Water Boiler

Based on the principles of thermodynamics and heat transfer, the burner is closely matched with the boiler to achieve the optimum ratio. Moreover, on the basis of traditional vertical hot water boilers, an integrated solution for waste heat utilization is added. The exhaust gas temperature is as low as 90℃, and the thermal efficiency is as high as 95%-96%. The efficiency of the boilers is maximized.

Features:

Rated thermal power: 0.35-0.7Mw

Rated thermal efficiency: 95-96%

Pressure: 0.1MPa

Available fuel: natural gas

COMMERCIAL BOILERS

H6 Gas Fired Hot Water Boiler

The boiler adopts advanced full premixed combustion technology to achieve super high utilization of fuel, and the operating efficiency is increased by more than 15% compared with ordinary boilers. The integrated structure design reduces the floor space by more than 30%. It is the preferred equipment for energy-saving heating in hotels, shopping malls and schools.

Features:

Rated thermal power: 0.7-2.8Mw

Rated thermal efficiency: 97.2-106%

Pressure: 0.1MPa

Available fuel: natural gas

T6 Vacuum Hot Water Boiler

The boiler adopts an environmentally friendly combustion method - full premixed combustion, and the gas and air are precisely adjusted and premixed in advance to ensure more complete combustion. The new crossing wing-shaped heat exchange element, Ultra-speed Smoke Cooking Tube, uses a unique heat transfer technology and structural design to achieve deep condensation of flue gas and greatly improve heat transfer efficiency.

Features:

Rated thermal power: 0.7-2.8Mw

Rated thermal efficiency: 105.5%

Pressure: -0.02MPa

Available fuel: natural gas

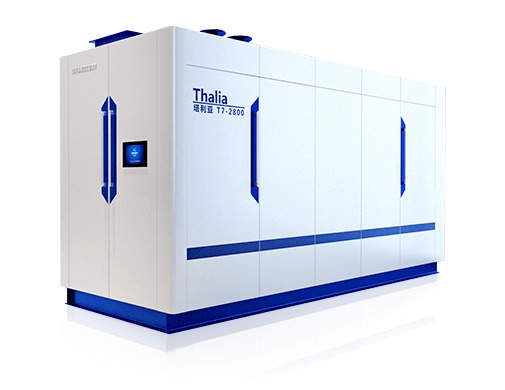

T7 Vacuum Hot Water Boiler

The deep matched technology of new combustion and heat transfer no longer sacrifices the boiler's key characteristics (heat transfer system) to adapt to the burner characteristics (combustion system), making the gas boiler a complete thermal system with low nitrogen emissions. At the same time of obtaining low nitrogen emission, the utilization efficiency of the boiler is further improved.

Features:

Rated thermal power: 2.8-7.0Mw

Rated thermal efficiency: ≥105.5%

Pressure: -0.02MPa

Available fuel: natural gas

V6 Gas Fired Hot Water Boiler

This series of boilers is a vertical structure. It uses advanced condensation technology to achieve condensation without a economizer. The overall footprint is only 1.4m³, and the exhaust temperature is as low as 50°C. It can continuously deliver hot water to schools, shopping malls, hotels, offices and other places.

Features:

Rated thermal power: 99Kw

Rated thermal efficiency: 97.2-104.4%

Pressure: 1.0MPa

Available fuel: natural gas

Electric Heating Boilers

Electric Steam Boiler

The boiler is composed of furnace, water supply, self-control, heating and safety protection system. It uses electricity to generate heat and generate steam with a certain pressure. It has the characteristics of convenient use, simple operation, economical and wide application fields.

Features:

Rated thermal power: 0.5-4.0 t/h

Rated thermal efficiency: 98%

Pressure: ≤1.25MPa

Available fuel: electric energy

Electric Hot Water Boiler

The boiler is composed of a boiler body, an electric control box and a control system, and has obvious characteristics of environmental protection, cleanliness, pollution-free, noise-free and automatic. With the reduction of limited energy and the sharp rise in price, electric hot water boiler as a new type of kinetic energy equipment is more and more recognized by people.

Features:

Rated thermal power: 0.1-2.8Mw

Rated thermal efficiency: 98%

Pressure: ≤1.0MPa

Available fuel: electric energy

BOILER PARTS

Circulating Pump

Circulating water pump refers to the circulating liquid pump for conveying reaction, absorption, separation and absorption liquid regeneration in boiler equipment. Its head is low, and it is only used to overcome the pressure reduction of the circulation system, and a low-lift pump can be used. The flow rate of the circulating water pump is medium, and under stable working conditions, the flow rate of the pump changes relatively little. Its head is small and low, and it is only used to overcome the pressure drop of the circulatory system. Low lift pumps can be used.

Water Tank

The water tank is generally composed of water inlet pipe, water outlet pipe (domestic water outlet pipe, fire water outlet pipe), overflow pipe, drainage pipe and other pipes. To measure the quality of the water tank, it depends on how the welding technology is. Welding materials should comply with the current standards "Carbon Structural Steel" and "Carbon Steel Welding Rod"; but welding is used for splicing steel plates, and other welding is fillet welds. Strengthen the coincidence.

Water Pump

The water pump is a mechanical accessory that transports liquid or pressurizes the liquid. It transmits the mechanical energy of the prime mover or other external energy to the liquid to increase the liquid energy. The liquids mainly used for transporting include water, oil, acid and alkali liquid, emulsion, Suspension emulsions and liquid metals, etc.; can also transport liquids, gas mixtures and liquids containing suspended solids. The technical parameters for judging the performance of the pump include flow rate, suction lift, head, shaft power, water power, and efficiency.

Water Softener

In the water supply process of industrial boilers, the main principle of using softened water is to use ion exchange resin to exchange iron, magnesium and calcium ions contained in water as sodium ions. Specifically, when the content of dissolved solids and various ions in tap water is known, the content of dissolved solids in demineralized water can be calculated simply by converting various ions in the liquid into sodium ions.

Sample Cooler

Sampling cooler is an instrument mainly used for sampling and cooling of steam and water in boiler room or power plant, including cooling water tank, water inlet pipe, flange cover, water outlet pipe, confluence tank and several cooling coils and other accessories; it can effectively improve water quality analysis accuracy, while connecting points between devices is simple. The sampling cooler is suitable for sampling high temperature liquids and gases, and has the advantages of compact structure, high heat transfer efficiency, convenient cleaning and long service life.

Threaded Pipe

Also known as low-ribbed tube, it mainly depends on the outer ribbing of the tube (ribing coefficient is 2-3) to expand the heat transfer area. The use of threaded tubes in boiler equipment can increase the heat transfer area by more than 1 times; and the surface tension inside the tube is strong, which also has a good strengthening effect on condensation and boiling outside the tube. Compared with the traditional smooth tube, it has the advantages of high heat transfer efficiency, not easy to scale, small size, and material saving.

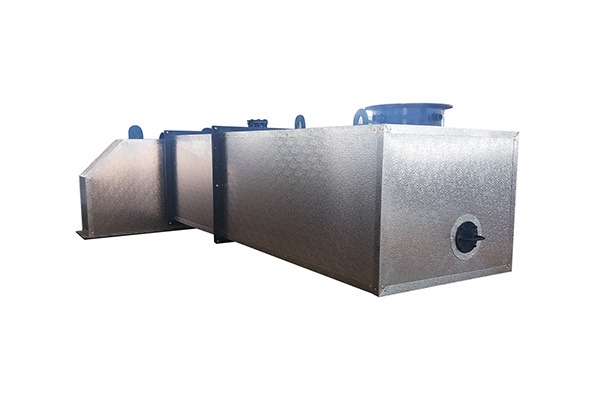

Continuous Sewage Expansion Container

The continuous blowdown expansion vessel is connected to the continuous blowdown port of the boiler. By decompressing and expanding the continuous blowdown of the boiler, the blowdown is separated into secondary steam and waste hot water by adiabatic expansion, which is expanded and depressurized in the expander, heat exchange and then discharge, secondary steam is led out by special pipeline, waste hot water is automatically discharged through floating ball liquid level valve or overflow regulating valve, and heat energy can be recovered and reused.

Condenser

In the system of oil-fired and gas-fired boilers, the condensing heat exchanger is the corresponding waste heat recovery and utilization equipment installed at the end of the boiler. If the flue gas is around the heat transfer surface, the corresponding near-wall surface temperature will gradually drop to the dew point temperature, which is accompanied by the cooling and condensation process of the water vapor, thereby releasing the corresponding heat and conducting the heat to the interior through the heat transfer surface. The specific working fluid is used, and then the heat in the exhaust gas is collected again, so as to achieve the purpose of energy saving and environmental protection of the system.

Energy Saver

The gas boiler economizer is mainly composed of flue heat exchanger, thermal insulation regulating water tank, circulating water pipeline, hot water circulating pump, solenoid valve, electrical control and monitoring and display system. Without changing the original body of the boiler, a flue gas heat exchanger is installed at the exhaust outlet to reduce the exhaust gas temperature of the boiler to a low enough level, and the superheated water vapor in the flue gas will condense, and through heat exchange It absorbs the physical sensible heat in the exhaust smoke and the latent heat of vaporization released by the condensation of water vapor.

Steel Chimney

With the continuous emergence of high-rise buildings, the setting of chimneys in high-rise buildings has attracted more and more attention, which is also a very difficult problem. If it is not handled properly, it is likely to cause serious consequences of "disaster to the present and future generations". The steel chimney made of stainless steel, titanium steel composite plate, carbon steel and other materials stands out because of its characteristics of heat preservation, effective durability, safety and reliability.

Sub-Cylinder

The sub-cylinder is also called the sub-drum, which is the main supporting equipment in the steam boiler. It is widely used in power generation, petrochemical, steel, cement, construction and other industries. It can distribute the steam generated by the boiler to various pipelines. The pressure-bearing equipment of the sub-cylinder system belongs to the pressure vessel, and its pressure-bearing capacity and capacity should correspond to the supporting boiler. The main pressure components of the sub-cylinder are: head, shell material, etc.

Valve

In boiler equipment, the valve can play the role of opening and closing the pipeline, controlling the flow direction, adjusting and controlling the parameters (temperature, pressure and flow) of the conveying medium. The valve is a control component in the fluid conveying system, which has the functions of cut-off, regulation, diversion, prevention of backflow, voltage stabilization, diversion or overflow and pressure relief. According to the specific function of the valve, it can be divided into shut-off valve, check valve, regulating valve and other models.

Regularly Drain And Expand The Container

The boiler regularly discharges sewage or waste hot water whose pressure is higher than that output by the regular blowdown expander, and separates secondary steam and waste hot water through decompression and expansion. The secondary steam can be discharged into the atmosphere or used as a heat source, and the waste hot water is generally discharged into the sewer system through the sewage cooling pool. In this way, the recovery of secondary steam and waste hot water can be used as a heat source, and a part of the heat loss caused by the boiler blowdown can be recovered, and the efficiency of the boiler can be improved.

Deoxygenation Pump

The deaerator pump needs to be used in conjunction with the deaerator in order to play a good deaeration function in the boiler equipment. Generally speaking, the selection of the deaerator pump should not only combine the flow-head curve, but also simulate the working curve after parallel connection through a certain selection software, and also leave a certain margin. Therefore, in the two When the deaerator pumps are connected in parallel, 5-10% of the space can be reserved according to experience, which requires the boiler engineer to have certain technical experience.

Deaerator

The deaerator is one of the key equipment in the boiler and heating system. It is mainly composed of the deaerator tower head, the deaerator water tank, as well as the connecting pipe and the external parts. If the deaerator's deoxidizing ability is poor, it will cause serious corrosion to the boiler's water supply pipeline, economizer and other ancillary equipment, and the economic loss will be dozens or even hundreds of times the cost of the deaerator. Everyone must pay attention to the quality selection of deaerators.

Burner

As the most important auxiliary equipment in boiler equipment, the quality of the burner will directly affect the operating efficiency of the boiler and the emission of nitrogen oxides. The burner is an integrated (split) burner designed and manufactured in accordance with relevant international and domestic standards. It adopts multi-stage combustion method and covers a wide range of furnace types. It can be used in water tube boilers, fire tube boilers, modular boilers, central return Types of boilers such as burning boilers.